Tropical Filler

For filling gaps, knots and cracks in wood manually

- Can be surface treated with both stain, lacquer, UV- and oxidizing oil

- Offers a countless number of colour options

- Made of natural raw materials

Product details

- Description

- Specifications

- Technical data sheet

- Safety data sheet

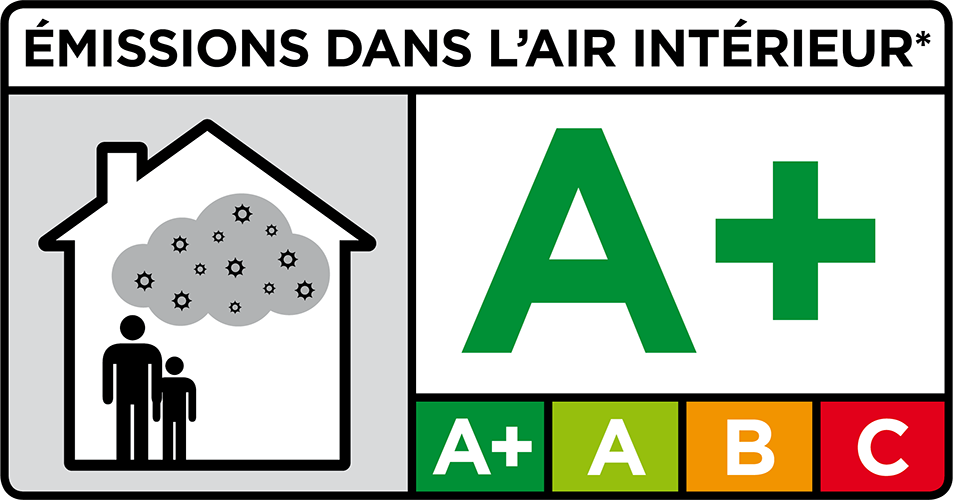

| COV: | 0 g/l, teneur maximale en COV (A/e (PS)): 400 g/l. |

|---|---|

| Densité: | 2.40-2.60 g/ml. |

| Valeur du pH : | pH 7-8 |

| durée de conservation: | 3 années |

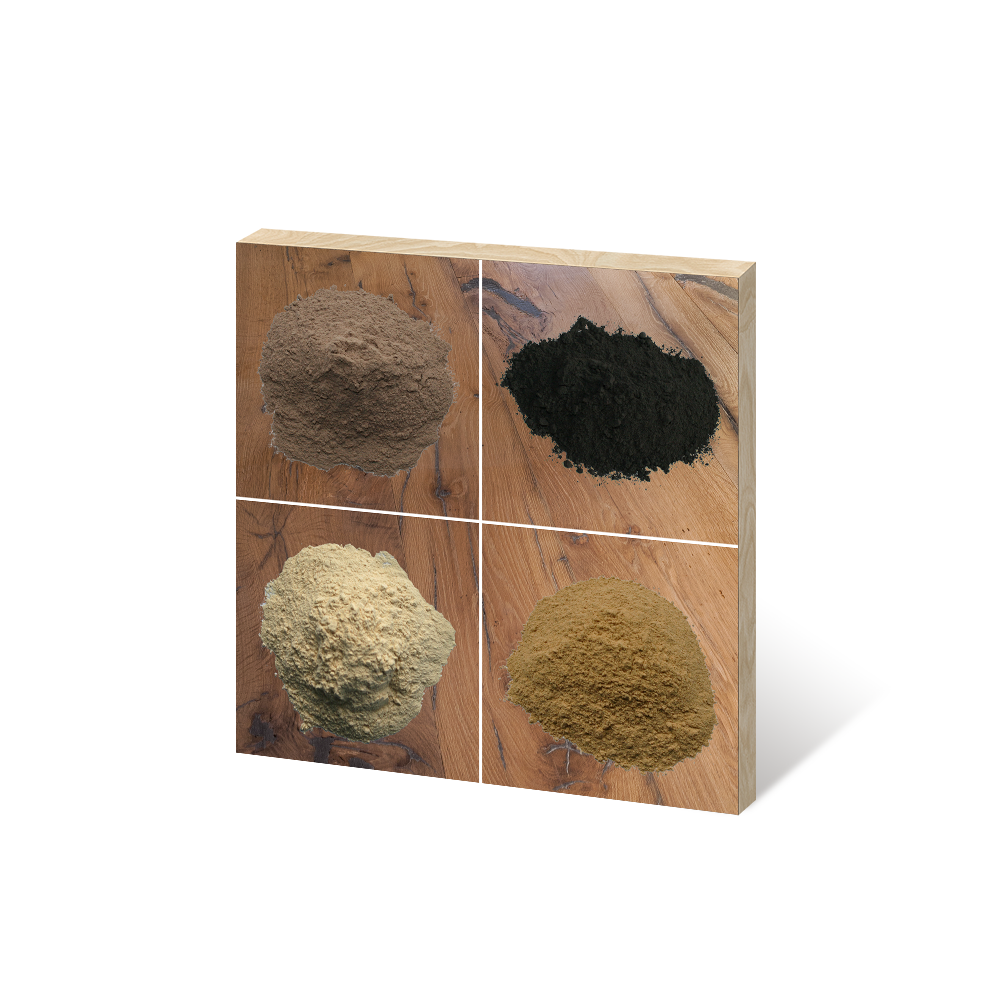

| Couleurs: | Chêne fumé, Chêne, Noir |

| Stockage: | +10-25°C. Tenir hors de portée des enfants. Ne pas exposer à la chaleur (par ex. au soleil). A conservez à l’abri du gel en hiver et au frais en été. |

| Emballage: | 20 L |

| Densité spécifique: | 2.20-2.40 g/ml. |

| Teneur en matière sèche: | 95-100% |

Tropical Filler is a high-quality environmentally-friendly powder-based filler that is easy to mix. It has the same qualities as the old WOCA Wood Filler, however the Tropical Filler is adjusted to fit the tropical climate (high humidity areas i.e. 80 %), but can also be used in areas with lower humidity. It is suitable for various types of repairs in wood and is applicable for wood repairs with a depth up to 15 mm. You can mix and match the different colours as you wish, but it is also possible to add colour pigment or stain to the mixture to obtain a customized colour. There is no expiration date on the raw powder if it is properly protected from moisture, water and foreign objects.

Worksteps

|

|

|

|

|